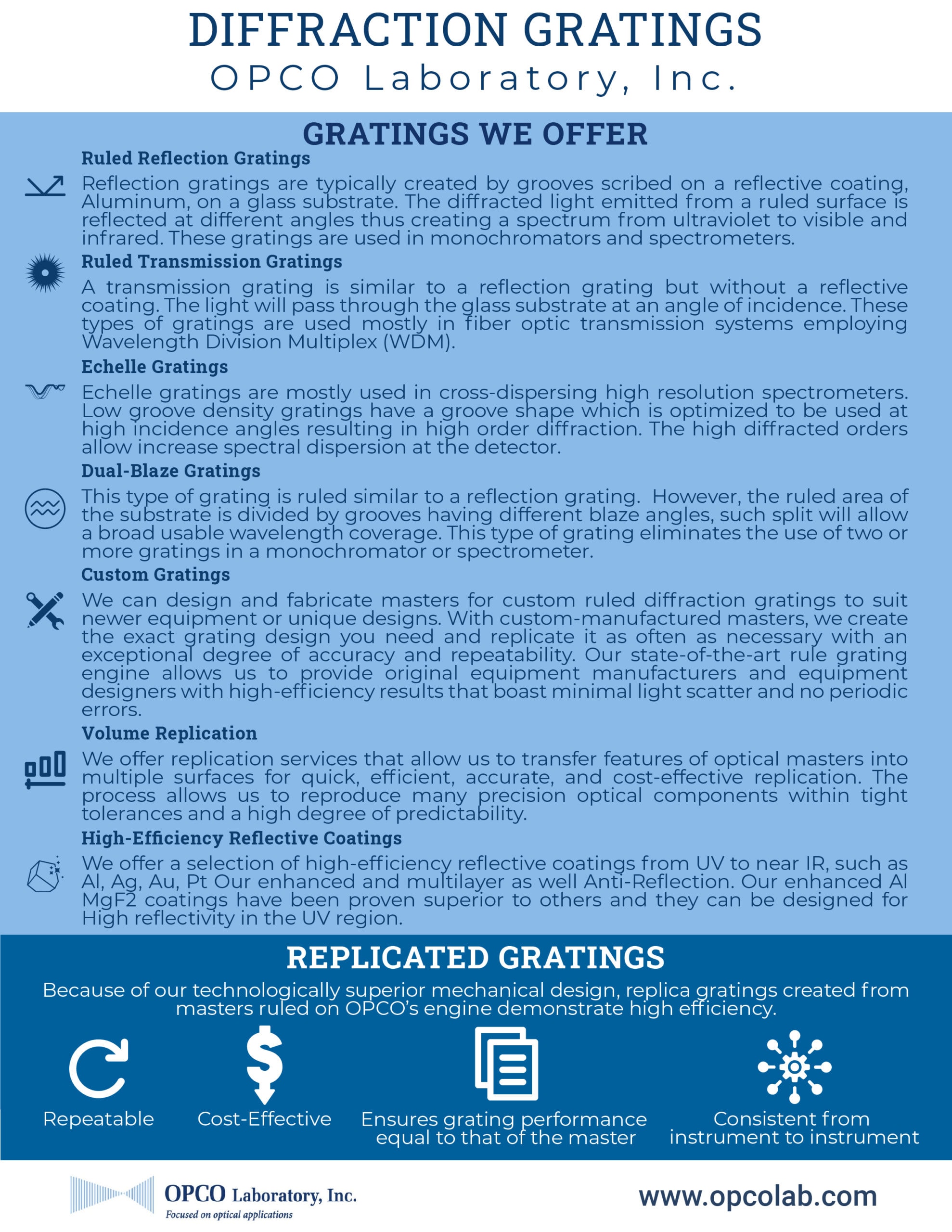

Ruled diffraction gratings separate light into different wavelengths using evenly spaced parallel slits, creating a clear separation between wavelengths. The division of light into different wavelengths allows users to conduct spectrographic analysis that determines atomic structure. Varying diffraction grating types provide precise division, intensity, and resolution in applications ranging from lab instruments to telescopes.

For more than 40 years, OPCO Laboratory, Inc. has been a leading provider of optical design and manufacturing services for customers in the life sciences, spectroscopy, material analysis, defense, aerospace, and semiconductor industries, among many others. OPCO is committed to using the latest technology to produce state-of-the-art optics equipment.

With our cutting-edge ruling engine we produce superior-quality stock and custom-designed gratings that will meet even the most stringent requirements. We incorporate advanced metrology such as interferometers, atomic force microscopes and spectrometers into our rigorous quality assurance procedures.

We have the knowledge, skill, and equipment necessary to fulfill your optical grating requirements. As an ITAR-registered company, we produce optics that meet and exceed industry standards across the board – including ruled diffraction gratings, both reflective gratings and transmission diffraction gratings.

OPCO Laboratory, inc. offers an extensive selection of stock and custom grating products and services, including:

- Ruled diffraction gratings. We create ruled diffraction gratings using ruling engines and diamond tools to produce grooves in reflective-coated glass, polymer, or crystal substrate. Our technicians calculate the cut angles and distances with extreme precision to facilitate the desired refraction. Available in reflection or transmission.

- Echelle gratings. Echelle gratings are a unique type of blazed gratings with a tiered shape, similar to a series of steps or stairs. The groove tiers intersect at right angles and allow the diffracted light to be dispersed in a series of overlapping orders.

- Dual-blaze gratings. These gratings, also referred to as double-blazed or two-zone gratings, have two unique series of grooves on their surface. These varied groove angles allow light to be dispersed at several angles, providing a broader overall wavelength response band.

- Volume replication. We offer replication services that allow us to transfer features of optical masters into multiple surfaces for quick, efficient, accurate, and cost-effective replication. The process allows us to reproduce many precision optical components within tight tolerances and a high degree of predictability. We can recreate transmissive gratings and reflective gratings using our advanced replication capabilities without the need for slower, more traditional grinding and polishing.

- High-efficiency reflective coatings. We offer a selection of high-efficiency reflective coatings that control the reflected wavelengths, helping prevent reflected waves from interfering with diffraction readings. Our selection of coatings includes enhanced Al/MgF2, gold, and platinum, among others.

Our Diffraction Grating Capability Specifications

Our extensive array of modern grating equipment allows us to produce gratings in a wide range of shapes, sizes, and materials. Our capability specifications are as follows:

- Materials: Fused silica, Borofloat®, Zerodur®, ceramics, aluminum, and more

- Dimensions: 5mm to 100 mm long

- Thickness: ≥ 1mm

- Surface Accuracy: λ/4 typical

- Shape: Square, round, rectangular, or customer-specified

- Grooves/mm: 30 to 3600

- Wavelength Range: UV to mid-IR

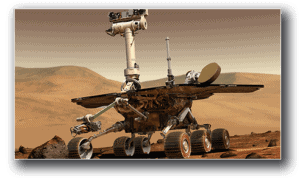

- Space Qualified: Currently part of the Mars ROVER ChemCam Spectrometers

Stock and Custom Diffraction Gratings

While there have been many advances in optics technology, the fundamental principles remain the same. Many masters for diffraction gratings in spectrometers, monochromators, and other standardized equipment are still in use. Our stock diffraction gratings feature cost-effective and more efficient production for traditional shapes and sizes, as there is no need to design or tool a new master.

OPCO Laboratory, Inc. can design and fabricate masters for custom ruled diffraction gratings to suit newer equipment or unique designs. With custom-manufactured masters, we create the exact grating design you need and replicate it as often as necessary with an exceptional degree of accuracy and repeatability. Our state-of-the-art rule grating engine allows us to provide original equipment manufacturers and equipment designers with high-efficiency results that boast minimal light scatter, no ghosts, and no periodic errors.

OPCO Laboratory, Inc. welcomes your request for custom-ruled, high-quality plane grating masters with virtually any groove frequency, blaze wavelength, and dual blaze wavelengths.

Applications of Diffraction Gratings

As a leading provider of quality diffraction gratings, OPCO Laboratory, Inc. has experience working with experts in a wide range of industries and applications, including:

- UV-VIS-IR spectroscopy: For solid and liquid measurements in industrial and teaching labs

- Monochromators and spectrographs: For sample analysis in biology, chemistry, biochemistry, and other fields

- Analytical instrumentation: Used in chemical, pharmaceutical, medical, and food processing applications

- Molecular analysis: Including HPLC, UV/VIS, NIR, IR, Raman

- Atomic analysis: Including ICP, Arc/Spark, AA, LIBS

- Telecommunication applications: Including WDM, DWDM, CWDM

- Laser tuning: For tunable lasers in semiconductor applications

- Metrology instruments: For a variety of measurement and calibration applications

OPCO’s Grating Ruling Engine

Most replicated ruled gratings produced today rely on masters created by decades-old ruling engine technology – often more than 30 years ago. Because of our technologically superior mechanical design, replica gratings created from masters ruled on OPCO’s new engine demonstrate high efficiency without the typical cosmetic imperfections seen in many of today’s grating offerings.

After five years in development, OPCO LABORATORY, INC. has announced its NEXT GENERATION RULING ENGINE for producing diffraction grating masters. This new, state-of-the-art ruling technology will permit us to make high-quality replica gratings from new master rulings more quickly and cost-effectively than traditional processes.

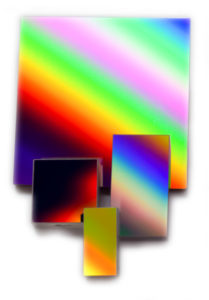

All OPCO LABORATORY, INC. gratings can be replicated for reflection or transmission onto various glass, metal, ceramic, or polymer substrates. Coating options for these replicas include high-reflectivity coating for reflection gratings or A/R coating for transmission gratings. OPCO’s proven replication process for gratings is repeatable and very cost-effective. Our process ensures grating performance equal to that of the master and consistent from instrument to instrument.

Diffraction Gratings & Optical Product Expertise from OPCO Laboratory, Inc.

The experts at OPCO Laboratory, Inc. will engage with your project to understand your spectrometer requirements and discuss how our replica gratings and assembly services can help you develop a quality, reproducible spectrometer. Our state-of-the-art facility and qualified staff can also support your needs for additional spectrometer components, including prisms, windows, lenses, beam splitters, spherical and toroidal mirrors, and more. As an ITAR-registered facility with comprehensive QA processes, you can expect the highest-quality diffraction gratings and other optical products available anywhere in the world.

Our staff spectroscopist and optical designers will help you choose the right grating and optics for your application. To speak to one of our experts about your project, please contact us or request a quote today.

Our Optics Are Out of This World!

OPCO provided several diffraction gratings that are integrated into the Spectrometers in the ChemCam Instrument Package mounted on the Curiosity Rover Vehicle.

Contact Ryan at OPCO to discuss how the quality of our NEXT GENERATION ruling engine can put you ahead of the competition.