Optical Replication Provides Cost-Effective, Volume Production of Complex Optical Surfaces

Overview

Replicated Optics achieve high optical accuracy and tolerances while realizing numerous benefits, particularly lower costs and reduced complexity.

Suited to applications requiring anywhere from only a few, to hundreds or even thousands of precision optical components, Replicated Optics include mirrors of nearly any surface shape or amplitude gratings, and with a range of coatings and substrates.

The replication manufacturing process produces components with a fraction of the processing time compared to conventional grinding and polishing, yet retains the high accuracy associated with grinding and polishing.

Furthermore, replicated optical components can often incorporate their own mounting holes and tabs, an additional source of significant cost, size, and weight savings for OEMs.

The result is higher light management quality for the cost, and the potential for reduced system weight, improved optical system stability, smaller system volume, placement of optics in tightly constrained spaces, fewer unique parts, and faster system assembly than any other available technology.

How the Replication Process Works

Once the optical design for the OEM application is tested in prototype systems and finalized, replication begins with manufacturing of a “master”. The master is produced using typical conventional machining, grinding, and polishing techniques. With the exception of replicating flat surfaces, the master is actually a negative of the final component since replication is a copying process where the final parts are made using the master as a tool.

The master is then tested and qualified to confirm that parts made from it will meet the requirements of the application. Surface accuracy and radii must be are certified to customer specifications using a laser interferometric measuring system, profilometer, or other measuring system depending on the optic configuration.

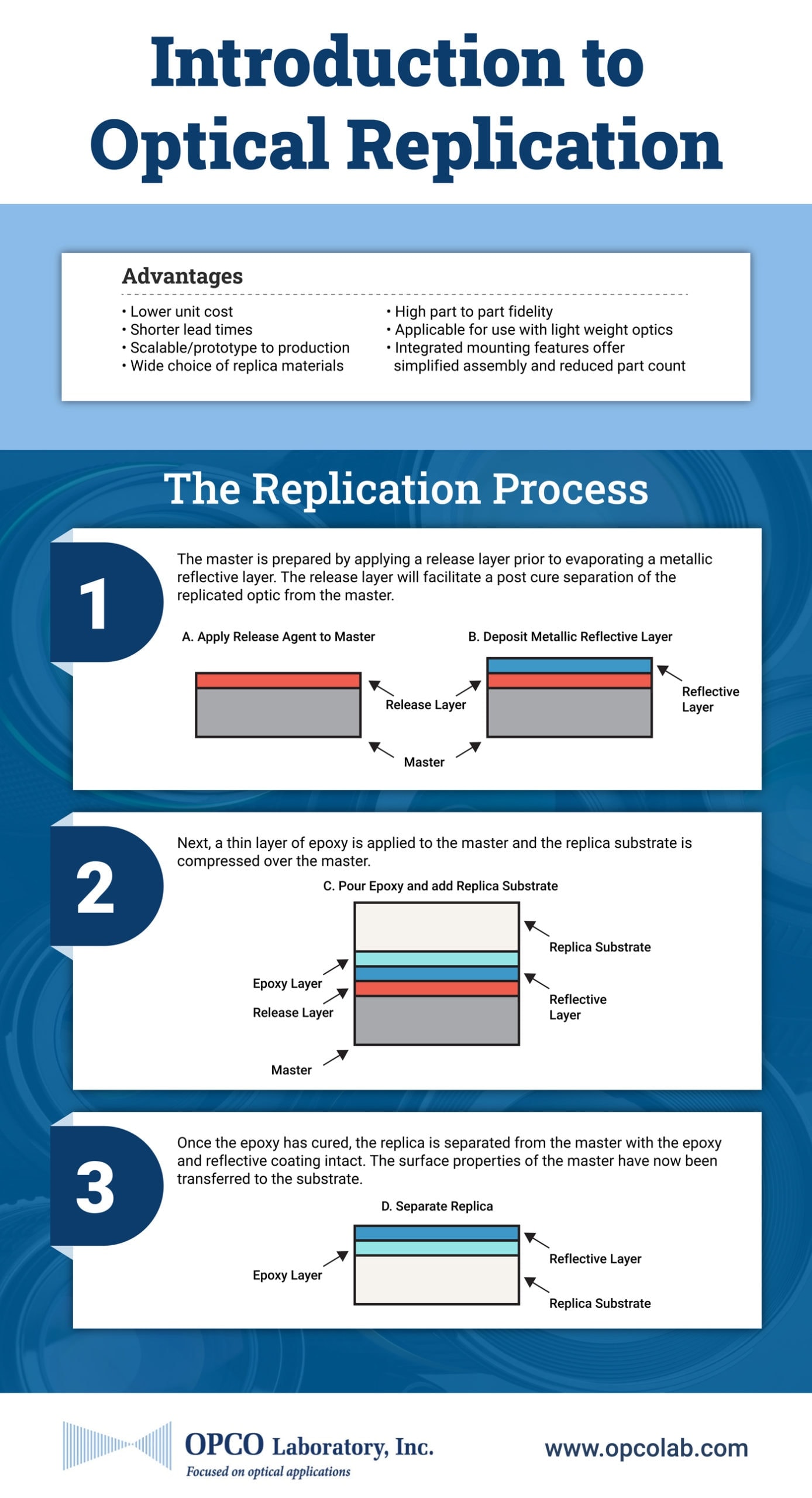

Once the master is validated, a release agent is applied to the master is first coated with a release agent to enable easy separation of the replicated component at the completion of the process. Next, any coatings that are required on the final part are applied, followed by the reflective layer.

Lastly, a film of engineered polymer epoxy is applied to either the master or the replicated component and the parts are joined for temporary permanent adhesion. After the polymer epoxy cures the replicated part is separated from the master.

The essential features of the replications process are:

- Suited to volume production (many parts from one or a few validated masters).

- Substrates do not require a precision machined surface because the epoxy layer accommodates machining imperfections; the final surface matches the master.

- Substrates can have built-in mounting holes, tabs, and unusual shapes to streamline assembly, minimize weight / inertia, and reduce unique parts count.

Limitations

Temperature

The principle limitation of replication compared to conventional production methods is the application temperature. Since the polymer epoxy used to create the replicated optic shape has a limited range, typically replicated optics can be used in systems that are limited to application temperatures in the range of -40°C to +125°C. Using replicated parts in higher temperature hotter applications is not possible.

Also, the upper temperature limitation of the polymer epoxy can limit the range of possible optical coatings since some types of coatings require coating chamber processes above +125°C.

Contact Ryan at OPCO to discuss replicating your optics.